Abstract

The purpose of this study was to investigate how cyclic loading influenced the fracture toughness of hot-press lithium disilicate and zirconia core materials and whether there was an increase in the propensity for crown failure. Two types of all-ceramic crowns including the IPS e.max Press system (n=24) and the Lava zirconia system (n=24), were selected. Sectioned specimens were subjected to cyclic loading with the maximum magnitude of 200 N (R=0.1) until two million cycles. The material properties including Young's modulus (E) and hardness (H) and the fracture toughness (KIC) of the core materials were evaluated using indentation methods (n=12 each). The load-bearing capacities of the specimens were examined by means of monotonic load to fracture (n=12 each). It was found that the material properties, including E, H and KIC, of the two types of dental ceramics, were reduced. Statistical analysis indicated that there were no significant influences of fatigue loading on material properties E and H for both types of dental ceramics or KIC for zirconia, while for the IPS e.max Press core, KIC, which was parallel to the direction of the lithium disilicate crystals, was significantly reduced (P=0.001). A conclusion was drawn that zirconia possesses high mechanical reliability and sustainable capacity to resist fatigue loading, while fatigue loading remarkably degraded the anisotropic mechanical behaviour of hot-press lithium disilicate ceramics.

Similar content being viewed by others

Introduction

All-ceramic dental restorations have been widely applied in prosthodontics because of their aesthetic, biocompatible and inert properties.1 Among the major shortcomings of brittle ceramics is susceptive to flaws and defects, which can develop as a result of thermal, chemical or mechanical processes. Thus, restorations are prone to catastrophic failure when subjected to tensile stress.2,3 Efforts to enhance the service life of all-ceramic materials have been undertaken to improve their strength (σ) and fracture toughness (KIC).

In recent decades, dental ceramics with high strength and toughness have been developed to meet the requirements of routine functions similar to the functions of teeth. Despite their general success, some all-ceramic crowns experience failure after years of service. As indicated in a clinical survey, the main cause of failure is fracture of the ceramics. Because the estimated survival rates of all-ceramic crowns were 97.3% at 5 years, 93.5% at 10 years and 78.5% at 20 years, their long-term success remains a major concern for restorative dentistry.4

Dynamic fatigue testing provides an efficient means for evaluating the long-term mechanical properties of materials under a constant cyclic stress ratio. Mechanical degradation in flexural stress and toughness has been realized in multiple dental ceramics,5,6 such as single ceramic crowns7 and dental bridges.1 The fracture toughness (KIC) is defined as the critical stress intensity factor at which a given flaw starts growing, and it indicates the intrinsic capacity of a material to resist rapid crack propagation and consequent catastrophic failure.8 According to the relationship of KIC and σ, based on linear fracture mechanics,  , σ was influenced by flaw size a. For dental ceramics containing flaws and defects, which can act as localized stress concentrators, although the stresses induced by low mastication loads do not exceed their characteristic strength, these stresses can promote subcritical crack growth, which results in substantial reduction of strength and potential catastrophic failure.9,10 Therefore, KIC is more predictive than strength,11 which has been widely accepted as a material parameter for the reliability assessment of ceramic materials.12,13

, σ was influenced by flaw size a. For dental ceramics containing flaws and defects, which can act as localized stress concentrators, although the stresses induced by low mastication loads do not exceed their characteristic strength, these stresses can promote subcritical crack growth, which results in substantial reduction of strength and potential catastrophic failure.9,10 Therefore, KIC is more predictive than strength,11 which has been widely accepted as a material parameter for the reliability assessment of ceramic materials.12,13

There are some methods for evaluating the fracture toughness of ceramics, including indentation fracture (IF),12 indentation strength,14 single-edge-notched beam15,16 and chevron-notched beam.17 Compared with the other methods, the IF technique, although it is not an accurate tool for determining the fracture toughness of unknown ceramic materials,18,19,20 requires only a small specimen size and uses simple experimental procedures,21 and has been widely accepted to measure KIC of brittle materials with Vickers indenter.12,22 In recent decades, some previous studies have measured the initial KIC of dental ceramics.3,21,23

Zirconia and lithium disilicate dental ceramics are widely used in China. A previous study reported that the facture strength of zirconia ceramics, regardless of the brand (Cercon smart, Lava, Porcera and CEREC 3), could be greater that 1 000 N.24 The overall load-bearing capacities of all-ceramic crowns could decrease after combined cyclic stress and moist and thermal cycling.25,26 Recently, the quasi-static fracture test showed that cement ageing caused by moisture could also result in a reduction of the load-bearing capacities of all-ceramic crowns.27 Because KIC is generally believed to be a material constant, whether the KIC of the dental ceramics and the load-bearing capacities of the layered structures are affected by fatigue loading have been of great interest to the practice of restorative dentistry. The purpose of this study was to evaluate the effects of fatigue loading on the fracture toughness and load-bearing capacities of these two types of dental ceramics. We hypothesized that the fracture toughness and loading-bearing capacities of the dental ceramics would significantly decrease after cyclic loading.

Materials and methods

Specimen fabrication

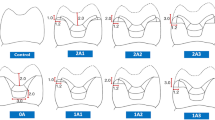

Two types of core veneered ceramics were fabricated, including the IPS e.max Press (Ivoclar-Vivadent, Schaan, Liechtenstein) pressable ceramic with IPS e.max Ceram (Ivoclar-Vivadent, Schaan, Liechtenstein) as the veneer and the zirconia core Lava (3M ESPE, Seefeld, Germany) for computer-aided machining (CAM) with Vita VM9 (Zahnfabrik, Bad Sackingen, Germany) as the veneer. Flat porcelain/ceramic bilayered specimens, with dimensions of 10.5 mm×2 mm×2 mm, as shown in Figure 1, were fabricated according to the manufacturer's instructions.28

The IPS e.max Press core, with a thickness of 0.8 mm, was veneered with 1.2-mm-thick IPS e.max Ceram, to obtain a total thickness of 2 mm greater that the substrate. The lower surface of the e.max Press core was etched with 4.5% hydrofluoric acid for 20 s, rinsed with plenty of distilled water and silanized and cemented to the Z100 (3M ESPE, St Paul, MN, USA) composite resin, thereafter acting as the dummy tooth substrate, with Rely X ARC (3M ESPE, St Paul, MN, USA) dual-cure resin cement. Vita VM9, with a thickness of 1.4 mm, was veneered on the 0.6-mm-thick zirconia core. Because excessive grinding or alumina abrasion could potentially introduce flaws and reduce the flexural strength of the zirconia core,29 in this study, the lower surface was roughened with 600-grit silicon carbide paper and cemented to the Z100 composite resin with Rely X ARC.

A total of 24 specimens were prepared for each type of the dental ceramic (lithium disilicate and zirconia). For each type of the dental ceramic, 12 specimens were randomly selected and subjected to cyclic loading. After fatigue, six specimens were randomly selected and subjected to monotonic load to fracture, and the other specimens were tested with nanoindentation and Vickers indentation. The remaining 12 specimens were tested as the control groups without fatigue. Similarly, six specimens were subjected to monotonic load to fracture, and the other six specimens were tested with nanoindentation and Vickers indentation. To conduct indentation tests, both sides of the specimens were successively wet ground to the required thickness with 320\600\800\1 200\2 000\3 000\5 000-grit silicon carbide (Matador, Wasserfest, Germany) mounted on the metallographic polishing machine (UNIPOL-830; Shenyang Kejing Auto-instrument, Shenyang, China). Note that nanoindentation was performed on one side of the specimen and Vickers indentation was performed on the other side.

Fatigue tests

During mastication, the restored posterior molar must withstand cyclic loads ranging from approximately 60 to 200 N.30 Under some severe conditions, such as clenching and grinding (bruxism), the maximum occlusal force can reach 500–800 N. As the number of chewing cycles per day was estimated at approximately 800–1 400, a moderate 500 000 cycles was considered to be the functioning cycle for the restored teeth per year.31 In this study, the mechanical behaviours of the restored crowns were evaluated after 4 years of service. For each type of ceramic, 12 specimens were randomly selected as a control group, and the others were subjected to cyclic loading. The specimens, exposed to air at room temperature, were subjected to sinusoidal fatigue loading in a fatigue test machine (BOSE ELF3300, BOSE, Minnetonka, MN, USA). As shown in Figure 1, the cyclic load (5 Hz) was applied at the center of porcelain surface with a tungsten carbide sphere (radius r=3 mm) at a maximum compressive load of 200 N (R=0.1 until two million cycles).

Monotonic load to fracture

The overall load-bearing capacities of the specimens were tested using monotonic load to fracture, and the ultimate load was recorded. Six specimens in the control group and six specimens after cyclic loading for each type of dental ceramic were subjected to monotonic load to fracture. The monotonic load was applied at the centre of the porcelain surface with a tungsten carbide sphere with a diameter of 6 mm using the Zwick BZ2.5/TS1S (model BZ2.5/TS1S; Zwick/Roll, Ulm, Germany) universal testing machine at a rate of 0.05 mm⋅min−1 in the displacement control mode.

Indention tests

The remaining six specimens in the control group and six specimens after cyclic loading for each type of dental ceramic were subjected to indentation tests. For each specimen, nanoindentation testing was performed at specified region (Figure 1) on one side to evaluate Young's modulus (E) of the core ceramics. Nanoindentation experiments were performed using the Hysitron Triboscope nanoindenter In-Situ Nanomechanical Test System (Hysitron, Minneapolis, MN, USA). A Berkovich indenter (TI-039; Hysitron, Minneapolis, MN, USA) was used, with a tip radius of approximately 200 nm. Loading was performed according to a triangular profile, with a maximum load of 4 mN and loading and unloading rates of 0.6 mN⋅s−1.

The hardness and fracture toughness of the ceramic cores were measured at the other side of the specimen using a Vickers hardness tester (HVS-10Z/LCD; Shanghai Taiming Optical Instrument, Shanghai, China) with a load of 98 N and a dwell time of 5 s for the zirconia core and with a load of 49 N and a dwell time of 5 s for the e.max Press core. The indent diagonal was oriented in the horizontal direction, while in the control groups indentation was also performed with 10° of rotation anticlockwise relatvie to the horizontal direction. The distance from crack-tip to crack-tip in the horizontal and vertical directions, along with the length of the indent diagonal, was measured immediately using an optical microscope at high magnification (×600). The values of Vickers hardness (H, GPa) were calculated according to ASTM C 1327-08,32,33 by the following equation:

where P was the applied load (N) and d was the mean value of the two diagonal lengths (mm). The indentation fracture toughness (KIC) was then calculated according to the following equation:13

In the above equation, E was the elastic modulus obtained from nanoindentation, H was the hardness obtained from the Vickers hardness test, P was the indentation load and c was the average crack length measured from the centre of the indent.

Statistics

Statistics were analysed using the one-way analysis of variance with Turkey's test (Statistical Package for the Social Sciences, SPSS, version 19.0; IBM, Armonk, NY, USA). Significant differences were identified by P<0.05.

Results

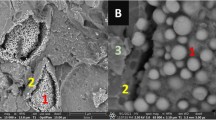

Two IPS e.max specimens were fractured at 1 600 000–1 800 000 cycles. An example of a fractured specimen is shown in Figure 2. From the fractographic analysis, the conic crack was first initiated in the veneer near the loading spot. With the growth of the cone cracks, they penetrated into the IPS e.max core and caused bulk failure. The other specimens remained intact after the completion of 2 000 000 cycles. Under these conditions, five IPS e.max Press specimens were randomly selected and subjected to monotonic load to fracture and the remaining five specimens were tested with indentation.

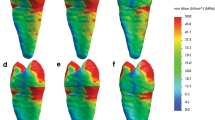

The elastic modulus, hardness and fracture toughness were measured with indentation and are listed in Table 1. The Young's modulus (E), hardness (H) and fracture toughness (KIC) of the zirconia core were significantly greater compared to the e.max Press core in both the control and experimental groups (P<0.05). Compared with the control group, the Young's modulus (E), hardness (H) and fracture toughness (KIC) of the zirconia core decreased, but there was no statistically significant reduction (P>0.05). As shown in Figure 3, the crack lengths induced by the Vickers indentation in the zirconia core were identical, indicating that zirconia remained mechanically isotropic after cyclic loading.

Interestingly, the lithium disilicate core behaved anisotropically. In the control group, the horizontal crack, which was parallel to the interface of the core and veneer, was longer than the vertical if the diagonal of the Vickers indenter was aligned in the horizontal direction (Figure 4a). The cracks redirected when the diagonal of the Vickers indenter was rotated (Figure 4b). According to the diagonal length of the crack displayed in Figure 4a and Equation (2), the mean magnitudes of fracture toughness in the horizontal and vertical directions were estimated as 1.16 and 1.87 MPa⋅m1/2, respectively.

The specimens that experienced cyclic loading were tested with the diagonal of the indenter aligned in the horizontal direction. The horizontal crack length was much longer than the vertical crack length, indicating that the anisotropy was more obvious (Figure 5). By substituting the crack length and corresponding mechanical parameters into Equation (2), the magnitudes of fracture toughness in the horizontal and vertical directions were calculated as 0.77 and 1.76 MPa⋅m1/2 respectively. The statistical analysis suggested that no statistically significant reduction in elastic modulus or hardness was detected in the lithium disilicate core after cyclic loading (P>0.05). There was no statistically significant reduction in fracture toughness in the vertical direction (P>0.05), but a remarkable reduction in the horizontal direction (P<0.05) was noted after cyclic loading.

The experimental results for monotonic load to fracture (Table 1) indicated that the ultimate compressive load for lithium disilicate was reduced from 857 to 645 N after cyclic loading (P<0.05), while the ultimate compressive load for the zirconia ceramics was greater 1 000 N and was not significantly influenced by cyclic loading (P>0.05).

Considering the limited number of specimens in the test groups, statistical power analysis was conducted to assess whether the sample size was sufficiently large to illustrate the differences in KIC and load-bearing capacities for the lithium disilicate crowns after fatigue. In the analysis, the probability of committing a Type I error, or false positive, was set at α=0.05. The probability β of committing a Type II error, or false negative, was calculated from the experimental results. The statistical power was accordingly determined as 1−β. The power analysis from the experimental results indicated that a sample size of 5 in each group was sufficient to demonstrate a difference at α=0.05.

Discussion

In recent decades, dental ceramics with high strength and toughness have been developed to meet the requirements of the routine functions of teeth. Despite their general success, some all-ceramic crowns have experienced failure after years of service.4 In this study, the laboratory evaluations of the mechanical properties of the dental ceramics and of the overall load-bearing capacities were conducted by considering the effects of the cyclic loading, which simulated the routine occlusal behaviours of the restored teeth. As a previous study indicated that the strength of ceramics was affected by flaw distribution,33 KIC was used to describe the capacity of dental ceramics to resist rapid crack propagation.

It has been reported that fatigue loading could reduce the mechanical strength of all-ceramic materials over time and could cause micro-flaws in veneer and core ceramics.10,34,35 Whether the KIC of the dental ceramics was affected by fatigue loading remains unknown. In the study, the magnitudes of KIC for the IPS e.max Press and Lava zirconia core before and after fatigue loading were compared using the IF method. The experimental results indicated the fatigue loading would cause distinct consequences in hot-press lithium disilicate ceramics, rather than in zirconia ceramics. It should be mentioned that due to its expediency, the IF method had been widely applied in measuring the KIC of brittle materials. However, IF was not an accurate method for measuring the true fracture toughness of materials because of the use of empirical parameters.36 IF is not recommended to measure the fracture toughness of unknown materials, although it is suitable for mechanical comparisons of the same material under varied conditions.

In the laboratory evaluation, the lithium disilicate behaved anisotropically. Prior to the fatigue loading, the KIC (1.16 MPa·m1/2) parallel to the direction of the veneer/core interface was less than the KIC perpendicular to the interface (1.87 MPa·m1/2). All these measurements were less than the initial KIC of zirconia (5.46 MPa·m1/2). This finding can be explained from the materials' microstructures. IPS e.max Press has needle-like lithium disilicate crystals with lengths of 3–6 µm that are embedded in a glassy matrix.37 The arrangement of lithium disilicate crystals, which was determined by the hot pressing direction,8,36 dictated the macroscopic anisotropic mechanical behaviour of IPS e.max Press. Cracks could redirect and grow in the same direction, with less resistance parallel to the needle-like crystals (Figure 4). The different crack lengths in two directions suggested that cracks propagating across the crystals were hindered by the aligned crystals as a result of the bridging and crack deflection.3

Although cyclic loading had trivial effects on the elastic modulus and hardness of the lithium disilicate, it caused a significant reduction in KIC in the primary direction of the lithium disilicate crystals. Thus, the hypothesis raised in the introduction was accepted for the lithium disilicate ceramics. considering the direction along the lithium disilicate crystals. This finding provides an informative evidence for technicians in designing hot-pressing paths while manufacturing lithium disilicate crowns, such as IPS e.max Press. In contrast, the recent development of CAD/CAM lithium disilicate has provided a promising method for dental restorations. CAD/CAM lithium disilicate blocks are manufactured with an optimized pressure-casting process to minimize microstructural defects. As the blocks are formed in an immediate phase due to partial crystallisation, they are easier to machine and can obtain high strength.38 Combined with aesthetic concerns, CAD/CAM lithium disilicate monolithic crowns could be used for single crown restoration in the anterior and posterior regions.39

Zirconia has symmetric crack lengths irrespective of the indenter's diagonal orientation (Figure 3) because zirconia possesses regular, fine grains with an average grain size of approximately 500 nm.40 A laboratory study indicated that the mechanical properties, including the Young's modulus (E), hardness (H) and fracture toughness (KIC), were not significantly influenced after two million cycles of fatigue with a maximum compressive load at 200 N (P>0.05). Zirconia has a stress-induced transformation-toughening mechanism. When zirconia is subjected to high stress, a structural transformation from the tetragonal to monoclinic phase (t→m) causes compressive stresses, which oppose the opening of cracks and improve resistance to crack growth.41 Thus, the hypothesis proposed in the introduction had to be rejected for zirconia ceramics. It should be noted that if the fatigue load or quasistatic load exceeded a certain threshold (more that 1 000 N), development of incipient cracks from the quasiplastic zone could have caused strength degradation in the zirconia ceramics.42

The ultimate load in the monotonic loading experiments showed that the load-bearing capacities of the zirconia system before and after cyclic loading were at the same level, also demonstrating that zirconia was unresponsive to cyclic loading from a macroscopic point of view. The dominant failure mode was chipping of the veneer with the zirconia core remaining intact regardless of the fatigue loading.43,44 This finding was consistent with findings from previous studies, which reported that cyclic loading did not significantly affect the mechanical strength of zirconia ceramics by applying cyclic biaxial flexural loading to ceramic disks,45,46 and the finding suggested that to improve service life, further investigations should focus on framework design modifications and refinement of the cooling parameters of veneering ceramics.39 Nevertheless, the load-bearing capacity of the lithium disilicate was significantly reduced after cyclic fatigue (Table 1). Cracks initiated in the veneer could penetrate into the lithium disilicate core, resulting in bulk failure of the specimen. Differences in the mechanical behaviours of zirconia and the lithium disilicate ceramics were created through fatigue loading.

Dental restorations function in a moist oral environment. In addition to mastication, the moisture might also influence the mechanical behaviours of restored teeth. Water could reduce the service life of restored crowns via two mechanisms. Relevant studies have reported the hydraulic pressure inside cone cracks could add additional stress intensity to crack tips and could accelerate crack growth in veneering ceramics.47,48 Furthermore, water-caused cement ageing could lead to loss of bonding strength and could significantly increase the flexural stress in the core.27 In this study, the fatigue test was conducted only in air, with the purpose of studying the influence of cyclic loading on the mechanical properties of two types of ceramic crowns. Only the effect of the fatigue on the mechanical degradation of ceramic crowns in air was obtained because both the control and test groups were tested in air concluded.

This study provides evidence that the fracture toughness of hot-press lithium disilicate would also decrease after years of service, without the influence of moisture. Clinical studies have demonstrated that zirconia ceramic restorations have had high success rates over a 5-year period.49,50 Although chipping or fracture of the veneering porcelain has been reported at a relatively high rate (15.2%), zirconia framework damage has rarely been reported.51 A comprehensive conclusion from these studies could be drawn that for zirconia crowns, a high-strength core is more durable, while greater attention should be paid to enhancing the strength of veneer ceramics. This study observed degradation of KIC and the load-bearing capacity of the hot-press lithium disilicate core after fatigue. However, the insight of transition into the microstructure requires further study.

Some limitations in this study should be mentioned. In this study, the sectioned, flat porcelain/ceramic bilayered specimens were examined, instead of clinically restored molar crowns. Obviously, the stress distribution in clinically restored molar crowns is more complicated than that in sectioned specimens. However, the basic fracture modes of the restored crowns and sectioned specimens are identical under contact loads.28 The advantage is that it is convenient to measure the mechanical properties of core materials and to identify the crack initiation and growth among the layers. This design has been applied in a series of studies and has proved effective in analysing the plastic damage and cement ageing in the dental layered structures.27,52 The daily functions of restored molar crowns include chewing and biting food. In this laboratory study, the cyclic load was only applied vertically to simulate the bite force, which predominantly causes the stresses in the layered structures, neglecting the stress caused by chewing movement.

Conclusion

This study used an experimental approach to evaluate the effects of fatigue loading on the fracture toughness and load-bearing capacities of IPS e.max Press and zirconia dental ceramics. Differences in mechanical properties after cyclic loading were observed in the two types of dental specimens. There was no significant influence of fatigue loading on the material properties (E, H) or KIC for zirconia, while for the lithium disilicate core, degradation of the anisotropic mechanical behaviour was observed. In detail, KIC, which is parallel to the direction of aligned lithium disilicate crystals, was significantly reduced (P=0.001). The load-bearing capacities of the lithium disilcate specimens were remarkably reduced as well. In comparison, the zirconia core possessed superior mechanical reliability and was suitable for posterior molar restorations, while the strength of veneering ceramics should be improved.

References

Studart AR, Filser F, Kocher P et al. Mechanical and fracture behavior of veneer-framework composites for all-ceramic dental bridges. Dent Mater 2007; 23( 1): 115–123.

Pegorin F, Kotousov A, Berto F et al. Strain energy density approach for failure evaluation of occlusal loaded ceramic tooth crowns. Theor Appl Fract Mec 2012; 58( 1): 44–50.

Albakry M, Guzzato M, Swain MV . Fracture toughness and hardness evaluation of three pressable all-ceramic dental materials. J Dent 2003; 31( 3): 181–188.

Beier US, Kapferer I, Dumfahrt H . Clinical long-term evaluation and failure characteristics of 1,335 all-ceramic restorations. Int J Prosthodont 2012; 25( 1): 70–78.

Zhang Y, Lawn BR . Long-term strength of ceramics for biomedical applications. J Biomed Mater Res B Appl Biomater 2004; 69( 2): 166–172.

Lohbauer U, Petschelt A, Greil P . Lifetime prediction of CAD/CAM dental ceramics. J Biomed Mater Res 2002; 63( 6): 780–785.

Borges GA, Caldas D, Taskonak B et al. Fracture loads of all-ceramic crowns under wet and dry fatigue conditions, J Prosthodont 2009; 18( 8): 649–655.

Scherrer SS, Denry IL, Wiskott AH . Comparison of three fracture toughness testing techniques using a dental glass and a dental ceramic. Dent Mater 1998; 14( 4): 246–255.

Mitov G, Gessner J, Lohbauer U et al. Subcritical crack growth behavior and life data analysis of two types of dental Y-TZP ceramics. Dent Mater 2011; 27( 7): 684–691.

Studart AR, Filser F, Kocher P et al. Fatigue of zirconia under cyclic loading in water and its implications for the design of dental bridges. Dent Mater 2007; 23( 1): 106–114.

Wang H, Isgrò G, Pallav P et al. Influence of test methods on fracture toughness of a dental porcelain and a soda lime glass. J Am Ceram Soc 2005; 88: 2868–2873.

Tang X, Nakamura T, Usami H et al. Effects of multiple firings on the mechanical properties and microstructure of veneering ceramics for zirconia frameworks. J Dent 2012; 40( 5): 372–380.

Gong J, Zhao Z, Guan Z . On the local crack resistance of Al2O3–TiC composites evaluated by direct indentation method. J Eur Ceram Soc 2001; 21( 7): 941–946.

Chantikul P, Anstis GR, Lawn BR et al. A critical evaluation of indentation techniques for measuring fracture toughness: II, strength method. J Am Ceram Soc 1981; 64( 9): 539–543.

Steinbrech RW, Knehans R, Schaarwachter W . Increase of crack resistance during slow crack growth in AIO bend specimens. J Mater Sci 1983; 18: 265–270.

Quinn JB, Sundar V, Lloyd IK . Influence of microstructure and chemistry on the fracture toughness of dental ceramics. Dent Mater 2003; 19( 7): 603–611.

Salem JA, Shannon JL . Fracture toughness of SiN measured with short bar short chevron-notched beams. J Mater Sci 1987; 22: 321–324.

Fischer H, Marx R . fracture toughness of dental ceramics: comparison of bending and indentation method. Dent Mater 2002; 18( 1): 12–19.

Morrell R . Fracture toughness testing for advanced technical ceramics: internationally agreed good practice. Adv Appl Ceram 2006; 105( 2): 88–98.

Quinn GD, Bradt RC . On the Vickers indentation fracture toughness test. J Am Ceram Soc 2007; 90( 3): 673–680.

Seghi RR, Denry IL, Rosenstiel SF . Relative fracture toughness and hardness of new dental ceramics. J Prosthet Dent 1995; 74( 2): 145–150.

Padmanabhan SK, Balakrishnan A, Chu MC et al. Micro-indentation fracture behavior of human enamel. Dent Mater 2010; 26( 1): 100–104.

Lohbauer U, Müller FA, Petschelt A . Influence of surface roughness on mechanical strength of resin composite versus glass ceramic materials. Dent Mater 2008; 24( 2): 250–256.

Wang R, Wang D, Xu Y et al. [Comparison of compressive strength and fracture mode between four kinds of CAD/CAM zirconia]. J Med Biomech 2011; 26( 5): 432–435. Chinese.

Jung YG, Peterson IM, Kim DK et al. Lifetime-limiting strength degradation from contact fatigue in dental ceramics. J Dent Res 2000; 79( 2): 722–731.

Kohorst P, Dittmer MP, Borchers L et al. Influence of cyclic fatigue in water on the load-bearing capacity of dental bridges made of zirconia. Acta Biomater 2008; 4( 5): 1440–1447.

Lu CL, Wang RR, Mao SS et al. Reduction of load-bearing capacity of all-ceramic crowns due to cement aging. J Mech Behav Biomed Mater 2013; 17: 56–65.

Zhang D, Zhang X, Lu C et al. Contact fracture of full ceramic crown subjected to occlusal loads. J Biomech 2008; 41( 14): 2995–3001.

Guess PC, Zhang Y, Kim JW et al. Damage and reliability of Y-TZP after cementation surface treatment. J Dent Res 2010; 89( 6): 592–596.

Anderson DJ . Measurement of stress in mastication: I. J Dent Res 1956; 35( 5): 664–671.

Kelly JR . Ceramics in restorative and prosthetic dentistry. Annu Rev Mater Sci 1997; 27: 443–468.

ASTM. Standard test method for Vickers indentation hardness of advanced ceramics. ASTM C1327-08. Conshohocken: ASTM, 2008: 1–8.

Guazzato M, Albakry M, Ringer SP et al. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part 1. Pressable and alumina glass-infiltrated ceramics. Dent Mater 2004; 20( 5): 441–448.

Chevalier J, Olagnon C, Fantozzi G . Subcirtical crack propagation in 3Y-TZP ceramics: static and cyclic fatigue. J Am Ceram Soc 1999; 82( 11): 3129–3138.

Studart AR, Filser F, Kocher P et al. Cyclic fatigue in water of veneer-framework composites for all-ceramic dental bridges. Dent Mater 2007; 23( 2): 177–185.

Moraes MC, Elias CN, Filho JD et al. Mechanical properties of alumina-zirconia composites for ceramic abutments. Mater Res 2007; 7( 4): 643–649.

Scientific documentation IPS e.max Press. Available at http://www.roedentallab.com/downloads/emaxpressdata.pdf. ( accessed 5 September 2012).

Kim JH, Lee SJ, Park JS et al. Fracture load of monolithic CAD/CAM lithium disilicate ceramic crowns and veneered zirconia crowns as a posterior implant restoration. Implant Dent 2013; 22( 1): 66–70.

Guess PC, Zavanelli RA, Silva NR et al. Monolithic CAD/CAM lithium disilicate versus veneered Y-TZP crowns: comparison of failure modes and reliability after fatigue. Int J Prosthodont 2010; 23( 5): 434–442.

Borchers L, Stiesch M, Bach FW et al. Influence of hydrothermal and mechanical conditions on the strength of zirconia. Acta Biomater 2010; 6( 12): 4547–4552.

Bocanegra-Bernal MH, Diaz de la Torr S . Review phase transitions in zirconium dioxide and related materials for high performance engineering ceramics. J Mater Sci 2002; 37( 23): 4947–4971.

Zhang Y, Pajares A, Lawn BR . Fatigue and damage tolerance of Y-TZP ceramics in layered biomechanical systems. J Biomed Mater Res B Appl Biomater 2004; 71( 1): 166–171.

Lorenzoni FC, Martins LM, Silva N et al. Fatigue life and failure modes of crowns systems with a modified framework design. J Dentist 2010; 38( 8): 626–634.

Ortorp A, Kihl ML, Carlsson GE . A 5-year retrospective study of survival of zirconia single crowns fitted in a private clinical setting. J Dentist 2012; 40( 6): 527–530.

Curtis AR, Wright AJ, Fleming GJ . The influence of simulated masticatory loading regimes on the bi-axial flexure strength and reliability of a Y-TZP dental ceramic. J Dentist 2006; 34( 5): 317–325.

Borchers L, Stiesch M, Bach FW et al. Influence of hydrothermal and mechanical conditions on the strength of zirconia. Acta Biomater 2010; 6( 12): 4547–4552.

Chai H, Lawn BR . Hydraulically pumped cone fracture in bilayers with brittle coatings. Scr Mater 2006; 55( 4): 343–346.

Zhang Y, Song JK, Lawn BR . Deep-penetrating conical cracks in brittle layers from hydraulic cyclic contact. J Biomed Mater Res B Appl Biomater 2005; 73( 1): 186–193.

Sailer I, Feher A, Filser F et al. Five-year clinical results of zirconia frameworks for posterior fixed partial dentures. Int J Prosthodont 2007; 20( 4): 383–388.

Molin MK, Karlsson SL . Five-year clinical prospective evaluation of zirconia-based Denzir 3-unit FPDs. Int J Prosthodont 2008; 21( 3): 223–227.

Denry IL, Baranta G, Holloway JA et al. Effect of processing variables on texture development in a mica-based glass-ceramic. J Biomed Mater Res B Appl Biomater 2003; 64( 2): 70–77.

Wang R, Lu C, Arola D et al. Plastic damage induced fracture behaviors of dental ceramic layer structures subjected to monotonic load. J Prosthodont 2013; 22( 6): 456–464.

Acknowledgements

This research was supported by the National Science Foundation of China (Grant No. 11172161), the Science and Technology Commission of Shanghai Municipality (Grant No. 10zr1423400), the Innovation Program of the Shanghai Municipal Education Commission (No. 12ZZ092), the State Key Laboratory of Oral Diseases (Sichuan University) (Grant SKLODSCU2009KF03) and the Shanghai Leading Academic Discipline Project (No. S30106). Technical support from the Instrumental Analysis and Research Centre at Shanghai University is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This work is licensed under the Creative Commons Attribution-NonCommercial-No Derivative Works 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Wang, RR., Lu, CL., Wang, G. et al. Influence of cyclic loading on the fracture toughness and load bearing capacities of all-ceramic crowns. Int J Oral Sci 6, 99–104 (2014). https://doi.org/10.1038/ijos.2013.94

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/ijos.2013.94

Keywords

This article is cited by

-

Do you know your ceramics? Part 5: zirconia

British Dental Journal (2022)

-

Fatigue resistance of monolithic lithium disilicate occlusal veneers: a pilot study

Odontology (2019)

-

Surface topography and bond strength of CAD–CAM milled zirconia ceramic luted onto human dentin: effect of surface treatments before and after sintering

Applied Adhesion Science (2018)

-

Major factors influencing proppant behaviour and proppant-associated damage mechanisms during hydraulic fracturing

Acta Geotechnica (2018)